Example Of In-Tank Filtration

Filtration Is Required

Effective filtration is a required step to eliminate the solids formed by the chemistry. Sizing and selecting of the filter is a function of metal removal per day.

PRO-pHx is a time lapsed reaction. Most results will not be seen for 1 to 3 days after adding PRO-pHx. Metals dissolved today are most likely being filtered from the acid in 2 to 3 days, not today. Organics may show a reaction in the first 24 hours. The reaction is less than 1 hour at temperatures of 160oF.

This is an in-tank filter. Filtration may vary from 1 to 100 microns. 5-50 microns are used most often.

The filter shown is Flo-King, which is suitable for small tanks (200 – 3,000 gal)

and all electroplating and electropolishing applications.

Example of Overflow Filtration

For a cleaner acid surface, an overflow technique can be used as shown here.

The acid overflows from the surface to an external tank and is filtered as it is returned to the main bath.

Example of Out-of-Tank Filtration

A filter press is connected externally to the bath for large volumes of solids.

Serfilco Filters

Serfilco’s MEGA-FLO filtration systems are compact, high flow, high capacity systems which are corrosion resistant. They are easy to install and simple to operate.

Serfilco Filter Cartridges

Filter cartridges can be cleaned and reused numerous times.

Siebec Filters

Siebec filters arecompact, high flow, high capacity systems which are good solutions for many applications. They are easy to install and simple to operate.

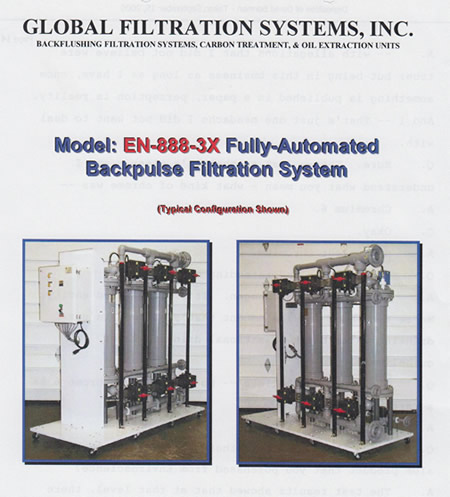

Global Filtration

Global Filtration is an excellent choice for high volume treatment tanks and when there is a waste treatment facility in-house.

Filtration Requirements:

On going filtration is suggested but may not be necessary for smaller baths. (They may require filtration only a few hours each day or each week.) As an example, a bath that is contaminated each week or each month has a different filtration requirement than a bath which is contaminated every 6 months.

Typical Filtration Setup:

Typical Plating or Galvanizing Line Using PRO-pHx Technology and Simple Filtration Systems For Zero Discharge of Acid and Rinses. View setup here:

http://www.pro-phx.com/typical_setup.htm

Filtration Micron:

Use effective filtration. Filtration may range from 1 to 100 micron. Most often used are 5, 10 and 50 micron filters. A general statement is that the less organics (coatings) introduced with the parts, the smaller the micron requirement. The fewer metals in the acid, the smaller the micron requirement. Only Copper in an acid metal may require 1 to 5 micron. Clean Iron, Zinc & Aluminum parts may require 5 or 10 micron. Cast Iron with coatings may require 50 or 75 micron filters.

If the filter is not building a filter cake, then the filter size may be too large. If the filter clogs immediately, then use a larger size micron. Once a contaminated acid is treated with

PRO-pHx and filtered clean, a smaller micron may be used for even cleaner acids. Determining the optimum filtration may take a little experimentation. Find the filtration that best suits your production and acid conditions.

Filter Cake Medium:

Filter cake can vary from a paste to a gel and can vary in color from black to white and the texture may vary from granular to a thick sludge, depending on the contaminates removed.

Filtration Tips:

The filtration isn’t building a filter medium/cake. If the filtration has been building a thick cake and this cake thins down without any major change in the production, try spiking a small amount of acid to the tank. This often reactivates the filtration performance of the treated acid.

The metals are climbing. If the metals numbers are climbing and the acid has been spiked and filtration doesn’t seem affect a result, then this is an indication that the total application of PRO-pHx has been diluted below the effective range of 1/2% to the total tank volume. Simply add an amount of PRO-pHx to restore the application to 1% to the total volume of acid & water in the bath. The acid & metals should once again stabilize in the range previously experienced.

Organics on the acid surface. Organics that sometime float to the surface of the acid rinse off easily and to date have not caused a down line plating problem. They may appear as a thin film, jell or foam. This filters out of the bath within hours and seems to have no adverse effects on plating results.

Large volume of organics in the acid. If organics are introduced into the acid in large volume, the Over Flow Filtration (see example in photo) technique can assist in maintaining cleaner acid surface.

Air or Mechanical Agitation may benefit the process. Mechanical or air agitation is not necessary but seems to be of some assistance. Avoid severe agitation as it may create a surface foam.

If you have specific questions or comments please contact us.