The following R&D and Case Studies have been presented as White Papers at Industry Forums, Conferences and Events:

Steel Conduit Galvanizing

PRO-pHx, Inc.

Acid Purification Technology

Application Success Story – Steel Conduit Galvanizing

Existing Problem:

The largest steel conduit galvanizing plant in the USA has 10 HCI, 5,000 gal HCI pickle tanks and one 3,500 gal sulfuric pickle tank also used for stripping. The customer chose to evaluate the chemistry on the 3,500 gal tank prior to full plant use. The 140 degrees F sulfuric tank was previously dumped every two months due to iron, zinc, and organic contamination. The spent acid was not suitable for beneficial reuse due to zinc.

Solution:

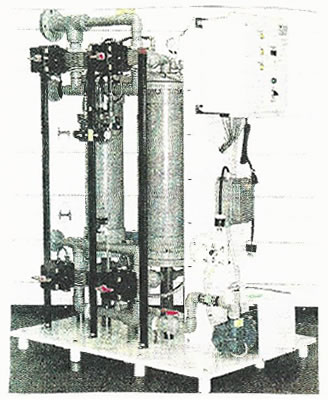

PRO-pHx chemistry addition at 1% with Global dual chamber filtration (as shown above) was initiated. After 7 months, the iron levels are maintained at less than 0.5% (verified by an independent laboratory) and with no issues with pickling and stripping. Galvanizing quality remained unchanged. The bath was recently used to strip zinc from 100 tons of rework in a 10-hour period. Regular production followed with no issues. Projected cost savings for this 3,500 gal sulfuric tank are estimated at $314,000.00 over 10 yeras. Additional benefits include:

- No Production Downtime for tank dumps

- Improved pickling speed and quality

- Reduced corporate liability for hazardous waste

- Reduced sulfuric purchases